Manufacturing Facilities

- Testing Facilities

- In-house Testing Facilities

1. PATTERN & DIE SHOP: Well equipped pattern shop for wooden/metallic patterns and aluminum dies.

2.MOULDING SHOP: Equipped with Pneumatic rammers & Sand compactors for hand moulding, employing Sodium-Silicate, NO-BAKE Oil Systems. stems.

3. MELTING SHOP: Equipped with two “INDUCTOTHERM” Make 350 KW & 175 KW Medium Frequency Induction Melting Furnaces, having Four Crucibles each of 650 KGS, 400 KGS, 200 KGS & 50 KGS of nominal capacity.

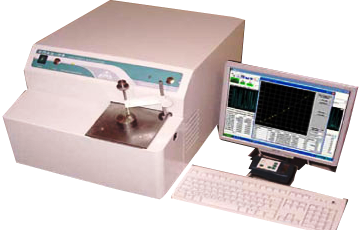

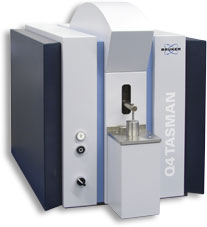

4. SPECTROMETER: Equipped with Two multi CCD dual optics spectrometers; Bruker Q4 Tasman (Germany) & SPECTRA plus-2110.

5. FETTLING SHOP: Well equipped fettling shop with heavy-duty swing frame grinders (6 Nos.), Flexible Shaft Grinder (11 Nos.), Sanders (02 Nos.) Pneumatic Chippers & STEEL BLASTING MACHINE (48” TABLE SIZE), Shot Blasting Machine.

6. LOST WAX CASTING EQUIPMENTS: Wax Injection Press , Wax Melting Machine, De-Waxing Tank, Knock Out Machine, Shell Baking Furnace, Slurry Stirrer & Rainfall Sender.

7. JOB CAPACITY:Weight Range: 0.060 KGS – 600 KGS SINGLE PIECE (Approx.)

8. STAND BY POWER SOURCE 250 KVA GREAVES DG SET

CRANES CRANES 5 MT - 1 No., 1 MT - 1 No.

9. HEAT TREATMENT SHOP:Equipped with 8’ x 5’ x 5’, 6’ x 5’ x 4’ electrical & 10’ x 8’ x 6’ oil fired Heat Treatment Furnace with Air, Water & Oil Quenching Facility. Equipped with “ATHENA”. Make microprocessor based Digital Temperature indicator & recorder & controller.

10. TEMPERATURE CONTROL: Pyrometer- LED displayed indicator along with sound buzz and data logger and Infrared temperature gun 0 to 1800* temperature measuring cap.

11.

MACHINE SHOP: Can be arranged for PROOF/FINAL MACHINING with arrangement for various machine tools like horizontal boring, Vertical lathe, conventional lathes, radial drill, gear hobbing, milling, shaping, grinding, planning & various other machines.

© 2012. All Rights Reserved.

Spectrometer

Bruker Q4 Tasman

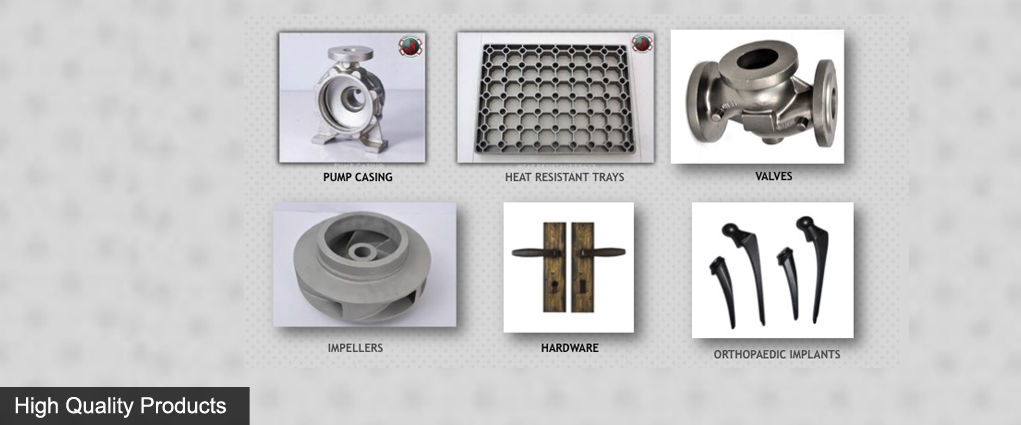

Stainless Steel Casting Manufacturers in Maharashtra | Pump Casting Manufacturers India | Special Alloy Steel Casting Manufacturers India | Cast Iron Casting Manufacturers India | Aluminium Casting Manufacturers India | Bronze Castings Manufacturers India | Gun Metal Casting Manufacturers India | heat resistant casting Manufacturers Mumbai | Inconel Casting in Mumbai | Super Alloys casting in india | High Cobalt Chromium Casting in india| Valve Casting Manufacturers Maharashtra